Rollforming Mills For Scaffolding Springboards

Rollforming Mills For Scaffolding Springboards consists of automatic decoiler, the guide and leveling, continuous punching device, forming part, length cutting portion, receiving station, electrical control cabinets and other components.

Advantage of our Rollforming Mills For Scaffolding Springboards:

1. Rollforming Mills For Scaffolding Springboards is controlled by PLC control system ,during normal work,it will more security.

2. The basic of Scaffolding Board Making Machine is middle plate,it will be welded and tempering to avoid the distortion.

3.The frame of machine is iron structure,it will tempering.After this process, it will more strong and long life.

4.Transmission structure for the gear box. Each rack has a gear box molding can ensure that equipment over time, high-intensity running, and long service life.

Basic information of Rollforming Mills For Scaffolding Springboards:

1,Working speed :2-8 m/min

2,Material thickness :1.0-1.2mm

3,Control system:PLC

4,Decoiler :5T

5,Punching :one set

6,Main roll forming rollers:16row rollers

7,Roll material:GCR15 Steel after quenching process HRC58-62℃,he chrome plating surface treatment

8,Material of the shaft and the shaft diameter:45# steel processing, shaft diameter is 70mm

9,Main machine power :18.5kw

10,Hydraulic station power:5.5kw

11,Hydraulic pressure:24Mpa

12,Scissors punching material:Cr12Mov,Quenching HRC 58-62℃

13,Length tolerance:3m±1.0mm

14,Voltage :380V, 50HZ,3 phrase

15,driving mode :chain driving mode

16,Machine size :16.5*2.2*1.6m

17,Delivery date :30 working days

18,Accessories:

1.Easy damaged parts: conk 2 pcs, fuse-link 4 pcs

2. Rubber mat 1 pcs; 3.Bolt spanner 1 pcs

19,Payment terms: Payment: 30% T/T in advance and balance 70% after, Inspection confirmation before shipment.

Delivery: within 45 working days after receipt of deposit

Detail introduction of each part:

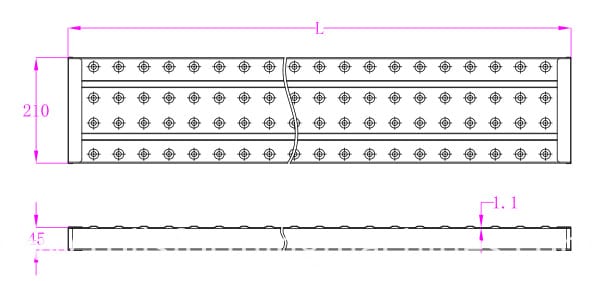

A profile drawing as reference:

Feeding and punching:

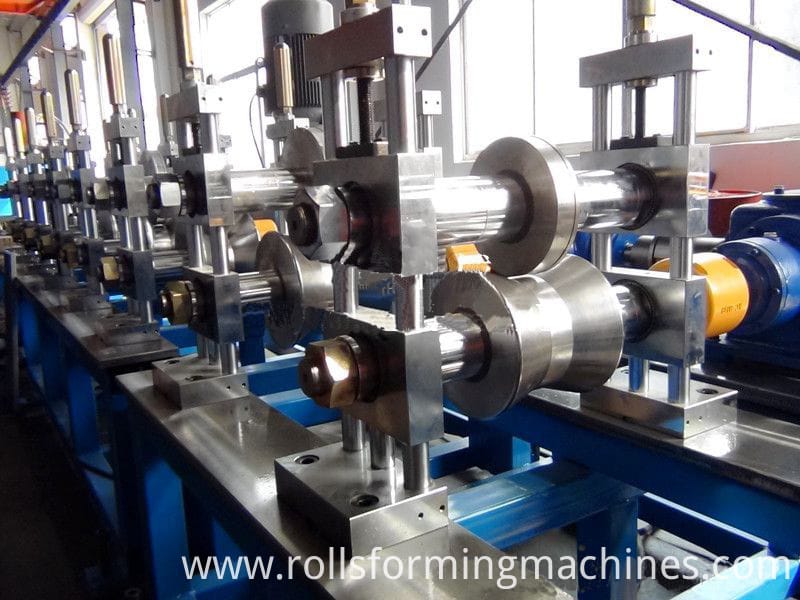

Roll forming for Rollforming Mills For Scaffolding Springboards:

Cutting part:

The final product of Scaffolding Springboards for you reference:

Looking for ideal Shelving Panel Forming Machine Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Lamp Frame Forming Machine are quality guaranteed. We are China Origin Factory of Scaffolding Springboards Mills. If you have any question, please feel free to contact us.

Product Categories : Special Equipment For Industry

Mr. Cary xu

Mr. Cary xu